In the realm of machining and metalworking, precision and accuracy are paramount. One tool that plays a pivotal role in achieving these goals is the سنبه پران mandrel. Whether you are a seasoned machinist or just beginning to explore the world of metalworking, understanding the significance and application of a cutting mandrel is essential.

What is a Cutting Mandrel?

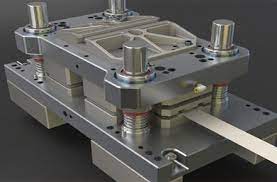

A cutting mandrel, often referred to simply as a mandrel, is a specialized tool used in machining processes to hold and support a workpiece securely. It is designed with precision and accuracy in mind, as it ensures that the workpiece remains perfectly centered during machining operations. This is crucial for achieving smooth, concentric cuts and minimizing any unwanted vibrations or deviations.

Versatility and Applications

One of the key strengths of cutting mandrels is their versatility. They can be employed in various machining processes, such as turning, milling, drilling, and grinding. Whether you are shaping a piece of metal, creating threads on a shaft, or boring holes with precision, a cutting mandrel is an indispensable companion.

Enhanced Efficiency and Accuracy

Using a cutting mandrel offers several benefits, foremost among them being enhanced efficiency and accuracy. By securely holding the workpiece, it reduces the chances of wobbling or misalignment during machining. This, in turn, leads to cleaner cuts, reduced scrap material, and a significant reduction in production time.

Choosing the Right Cutting Mandrel

Selecting the appropriate cutting mandrel for a specific task is crucial. Factors such as the workpiece material, size, and the machining operation at hand must all be considered. Additionally, ensuring that the mandrel’s design and quality meet industry standards is essential for achieving the desired results.

Conclusion

In the world of machining and metalworking, the cutting mandrel stands as a testament to precision and efficiency. Its ability to securely hold workpieces, minimize vibrations, and maintain concentricity makes it an indispensable tool for machinists across industries. Understanding the different types of cutting mandrels and their applications is the first step toward achieving superior machining results.